Mechanical Engineering

Department of TechnicalsMechanical engineers create the world around us. From the smallest nanotechnology to cars and buildings, to space stations and airplanes, mechanical engineers are responsible for the design as well as the development of most things.

Studying vocational in mechanical engineering is a combination of maths, science, and computing. It’s the study of machinery, and how to mass produce and maintain it at all levels. It’s a boundless subject, which plays a role in everything from vehicles to cities, energy to artificial intelligence, military to healthcare, and everything in between.

Key Feature

- Teaching and general pedagogy focus on theoretical education and training, and on developing the education system and teaching curricula.

- Diagnostics and support deal with learning procedure diagnostics, heterogeneity in individual support approaches, schools, and performance assessment.

- Professional training in schools and companies comprises content on vocational education and the specific structure conditions of the vocational college.

- Technology training provides two courses involving practical exercises and theories to learn how to teach technical knowledge

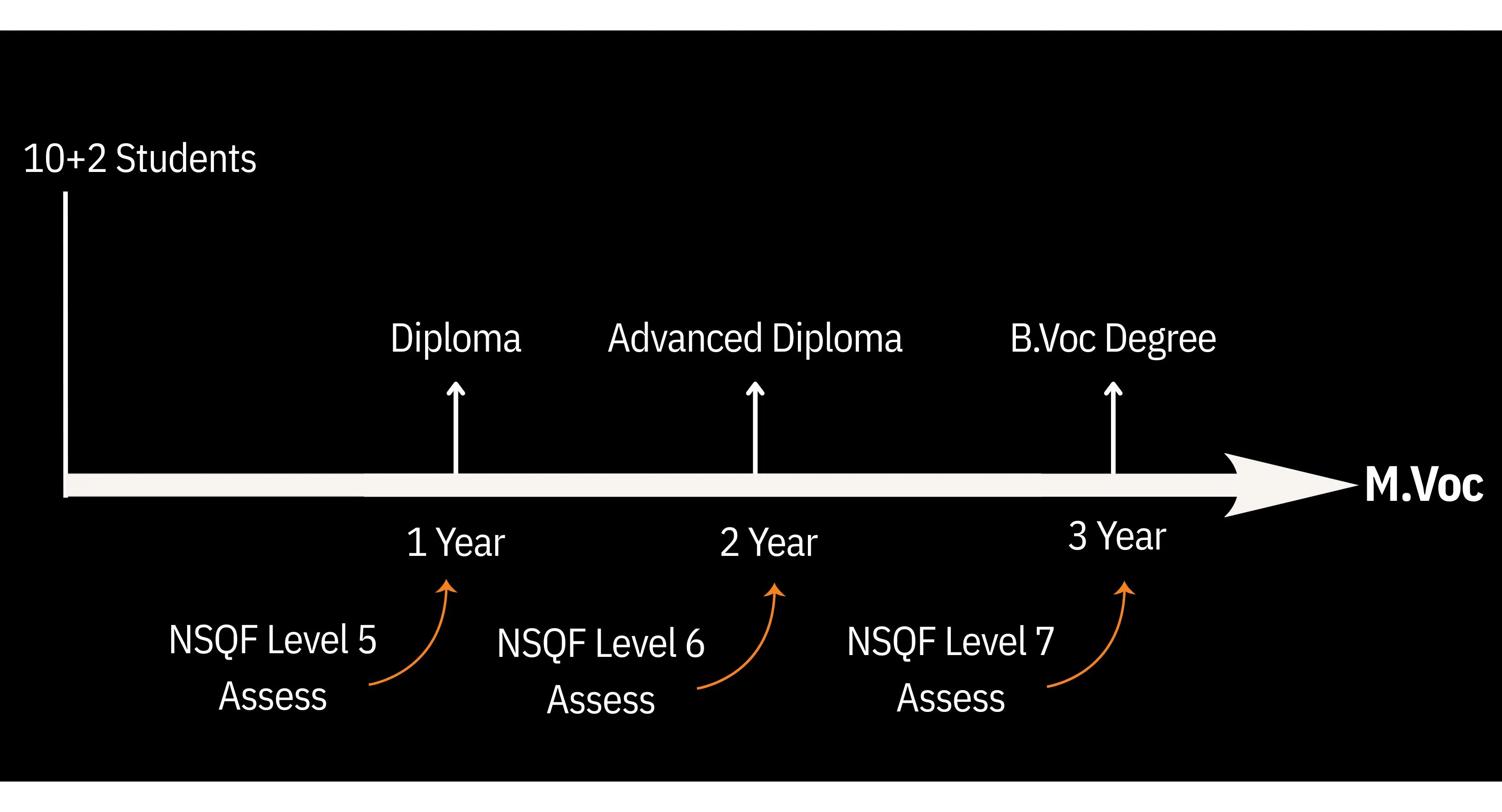

Course Progression: Mechanical Engineering

Diploma (First Year – Semester 1 & 2)

A strong foundation in core mechanical systems, materials, and industrial processes.

- Start with fundamentals like Applied Physics, Applied Mathematics, and Machine Tool Technology, building the core of mechanical problem-solving.

- Start with fundamentals like Applied Physics, Applied Mathematics, and Machine Tool Technology, building the core of mechanical problem-solving.

- Understand machine behavior through General Mechanical Engineering and hands-on Vocational Practical sessions.

- Strengthen workplace skills with Computing Skills, Functional English, and practical workshops that align with modern vocational programs.

- Move into industry-oriented subjects such as Production Technology, Metrology, Manufacturing Technology – I, and Industrial Management.

- Learn quality and operational fundamentals through Total Quality Management and Basics of Economy and Market — essential for future engineers in any engineering university or technical program.

Advanced Diploma (Second Year – Semester 3 & 4)

Transition into mechanical systems, manufacturing processes, and mechatronics.

- Deepen your technical base with Material Science, Manufacturing Technology – II, and General Mechanical Engineering – I.

- Begin integrating electronics into mechanical systems through Fundamentals of Mechatronics.

- Strengthen workplace readiness with Communication Skills and Financial Literacy.

- Explore advanced engineering concepts like Tool Engineering, Agile & Lean Manufacturing Systems, and Metal Forming Processes.

- Build logical and computing capabilities through Computing Skills-II and Basics of Accounting.

- The perfect stage for students preparing for a bachelor’s in mechanical engineering through the B.Voc pathway.

- Work with high-precision systems through Mass Production Devices, Design Concepts in Engineering, and Product Design & Development.

- Step into digital engineering tools like CAD & CAM, widely used in global manufacturing industries.

- Learn futuristic processes through Rapid Prototyping & Reverse Engineering, essential for modern machine engineering roles.

- Strengthen digital capabilities with Digital Literacy.

- Final year enhances professional readiness with Process Planning, Cost Estimation, Tool & Die Making, and Entrepreneurship.

- Conclude with a major industrial project, showcasing your abilities in modern technology training and vocational education.

B.Voc Degree (Third Year – Semester 5 & 6)

Industry-focused specialization, product design training, and real-time project experience.

M.Voc Degree (Postgraduate Level – 2 Years)

Advanced manufacturing, automation, machining science, and research excellence.

Year 1 – Advanced Mechanical Systems & Intelligent Manufacturing

- Strengthen analytical ability through Advanced Mathematics and Operational Management.

- Dive deeper into machining with Principles of Machining Process and Hydraulics & Pneumatics.

- Learn advanced computer-aided design tools via Computer Graphics and CAE.

- Explore modern machining methods, Numerical Control of Machine Tools, and Non-Traditional Machining.

- Enhance innovation through Reverse Engineering & Rapid Prototyping and advanced Mechatronics.

- Strengthen understanding of customer-driven design with Quality Function Deployment.

Year 2 – High-End Intelligent Manufacturing & Research

- Advance analytical and optimization skills through Discrete Structure, Optimization, and Instrumentation & Measurement.

- Understand real-world behavior of materials through Experimental Stress Analysis and Mechanical Behavior of Materials.

- Learn industrial transformation methods such as Business Process Reengineering (BPR).

- Move into futuristic technologies like Robotics, Holonic Manufacturing Systems, and Principles of Machine Design.

- Finalize the degree with Research Methodology and a comprehensive Dissertation, preparing you for leadership roles across manufacturing, design, automation, and industrial engineering.

-min.jpg)